Precision in Production: Mastering the Art of Crafting Durable Expanded Metal Mesh

One such material that has been a cornerstone of various sectors is expanded metal mesh.In the world of industrial applications, precision is not merely a buzzword; it is a fundamental principle that drives innovation and excellence. As industries continue to evolve, the demand for durable and reliable materials is ever-growing. With its unique properties and versatility, expanded metal mesh finds applications in construction, automotive, filtration, architecture, and more. This article delves into the art of crafting durable expanded metal mesh, exploring the precision-driven production processes that contribute to its remarkable strength and longevity.

The Science Behind Expanded Metal Mesh: A Brief Overview

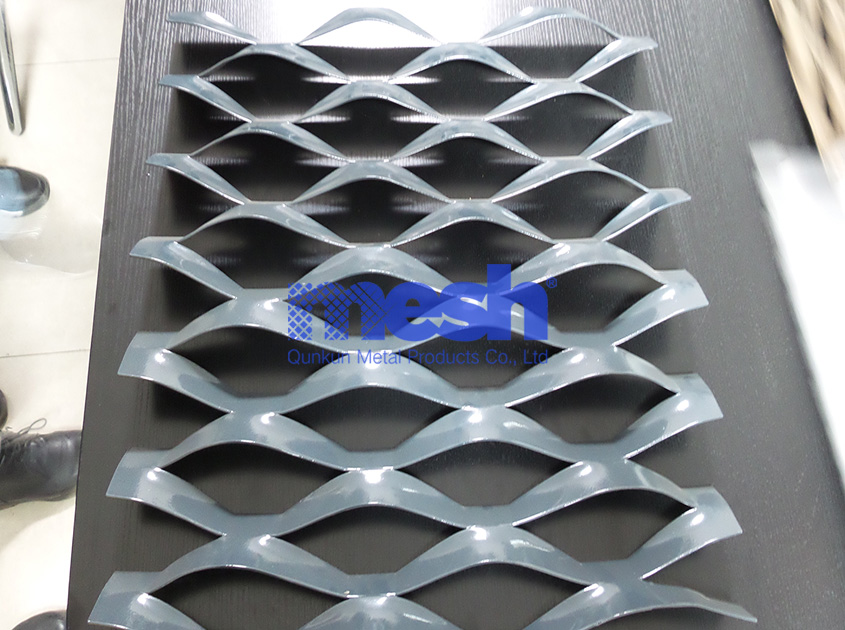

Expanded metal mesh is a three-dimensional mesh-like structure formed by cutting and stretching a sheet of metal. This intricate pattern results in a robust and lightweight material that offers exceptional strength-to-weight ratio, excellent ventilation, and effective light diffusion. The manufacturing process plays a pivotal role in determining the quality and durability of the final product.

Precision-Cutting Techniques: Elevating Quality Standards

Precision begins with cutting. Advanced cutting techniques such as laser cutting and water jet cutting ensure the accuracy and consistency of the patterns. These methods not only enhance the visual appeal of the mesh but also contribute to its overall structural integrity. The intricately designed patterns provide optimal load distribution and prevent stress concentrations, thereby significantly extending the lifespan of the expanded metal mesh.

In a world where durability, precision, and performance are paramount, the craftsmanship behind producing expanded metal mesh stands as a testament to human ingenuity and engineering excellence. From the initial design and material selection to the precise cutting and expansion processes, every step plays a crucial role in creating a product that is not only aesthetically pleasing but also robust and reliable. As industries continue to evolve, the pursuit of precision in producing expanded metal mesh remains unwavering—a pursuit that shapes the future of various sectors and paves the way for innovation and progress.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China